Understanding the Vital Role of Cummins Original Parts in Diesel Engines

Cummins original parts are not just components; they are the essence of reliability and performance in diesel engines. Whether you are a diesel engine manufacturer or a diesel generator supplier, understanding the significance of these original parts can lead to better performance, efficiency, and ultimately, customer satisfaction.

The Importance of Original Parts

In the world of diesel engines, the quality of parts can substantially affect performance, longevity, and operational efficiency. Here are several reasons why opting for Cummins original parts is imperative:

- Quality Assurance: Original parts are manufactured to the highest standards, ensuring they fit seamlessly with your engine's architecture.

- Performance Enhancement: These parts are designed specifically to enhance the performance of Cummins engines, leading to improved power and torque delivery.

- Durability: Original parts possess superior longevity, reducing the frequency of breakdowns and failures.

- Warranty and Support: Using original parts typically guarantees better warranty protection and manufacturer support, safeguarding your investment.

Cummins Original Parts: Types and Applications

Cummins offers a wide array of original parts that cater to various engine types and applications. Below are some key categories:

1. Engine Components

Essential components that directly influence engine health include:

- Pistons: Critical for maintaining engine compression and performance.

- Cylinders: Designed for optimal heat dissipation and durability.

- Valves: Ensure efficient gas exchange and performance under stress.

2. Fuel Systems

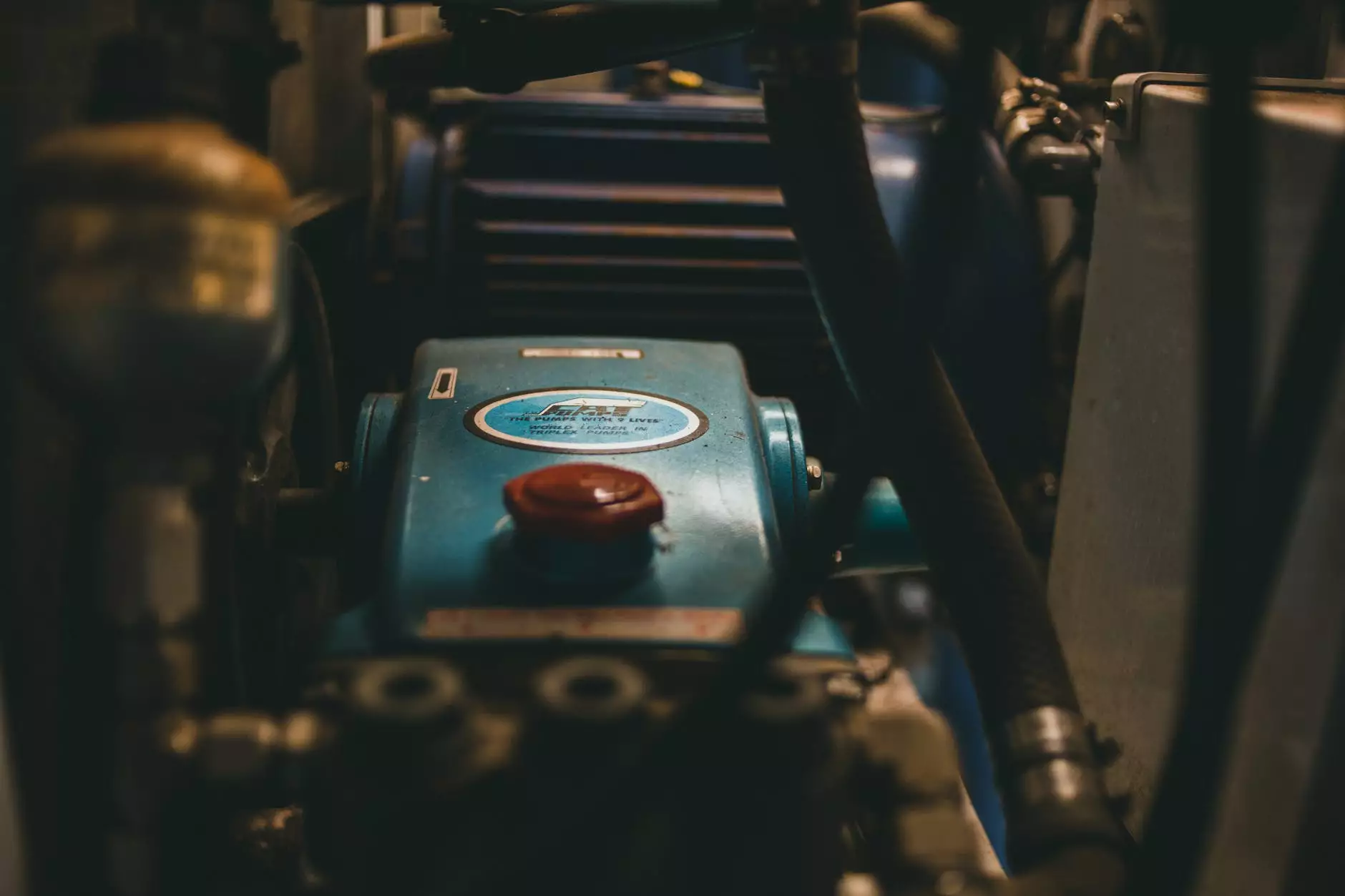

Fuel systems are pivotal for the smooth operation of diesel engines. Key components include:

- Fuel injectors: Deliver accurate amounts of fuel for combustion efficiency.

- Fuel pumps: Ensure consistent fuel supply under various engine loads.

3. Electrical Components

Every diesel engine relies on electrical systems that need to be reliable:

- Starters: Essential for engine ignition.

- Alternators: Generate body power to keep the electrical system running.

4. Cooling Systems

Maintaining the right operating temperature is crucial. Components include:

- Radiators: Facilitate effective coolant circulation.

- Water pumps: Ensure proper coolant flow throughout the engine.

Benefits of Using Cummins Original Parts

Using Cummins original parts provides numerous benefits

- Enhanced Reliability: These parts are built for your specific engine model, eliminating compatibility issues.

- Increased Efficiency: With components designed for optimal performance, your engine operates more efficiently.

- Cost-effectiveness: While initial costs may be higher, using original parts reduces long-term maintenance and replacement costs.

- Improved Resale Value: A vehicle with original parts retains higher resale value than one fitted with non-original components.

How to Source Cummins Original Parts

Sourcing Cummins original parts can be straightforward if you keep the following steps in mind:

1. Authorized Dealers

Identify authorized Cummins dealers or distributors to ensure you are purchasing genuine parts. Authorized dealers offer a range of parts, along with valuable advice and support.

2. Online Platforms

Several online platforms specialize in Cummins original parts. Ensure that the platform is reputable, offers warranties, and has a return policy for peace of mind.

3. Local Mechanics and Technicians

Your local diesel mechanics or technicians often have connections with suppliers and can assist you in sourcing original parts.

Cummins Parts and Maintenance

Regular maintenance is essential to ensure the longevity of your diesel engine. Incorporating Cummins original parts into your maintenance routine ensures consistent performance. Here’s how to maintain your engine effectively:

- Regular Inspections: Frequent checks on engine parts can identify potential issues before they become serious.

- Scheduled Replacements: Following a recommended schedule for replacing parts can help maintain efficiency and prevent breakdowns.

- Utilizing Professional Services: Employing certified Cummins service technicians ensures that all replacements are done according to manufacturer specifications.

Case Studies: The Impact of Using Original Parts

Numerous case studies illustrate the difference that Cummins original parts can make:

Case Study 1: Increased Engine Longevity

A logistics company experienced frequent engine failures due to aftermarket parts. After transitioning to Cummins original parts, they reported a significant increase in engine life, reducing downtime and maintenance costs considerably.

Case Study 2: Improved Fuel Efficiency

Another case involves a construction firm that replaced fuel injectors with original parts, resulting in a measurable decrease in fuel consumption and emissions, proving that quality parts can enhance operational efficiency and sustainability.

The Future of Diesel Engines and Original Parts

As advancements in technology reshape the diesel engine landscape, the importance of original parts remains unwavering. Innovations in manufacturing, material science, and design promise to enhance the capabilities of diesel engines even further. However, the core principle for ensuring performance will always center around using genuine components like Cummins original parts.

Conclusion

Investing in Cummins original parts is investing in performance, reliability, and the future of your diesel engine. By choosing original over aftermarket options, you secure not just the best components for your fleet but also peace of mind, knowing that you are backed by the Cummins commitment to quality.

For those in the diesel engine manufacturing and generator supplying business, the choice is clear. Utilize original parts, maintain your equipment diligently, and reap the benefits of enhanced performance and reliability.

For more insights and quality parts visit engine-family.com.